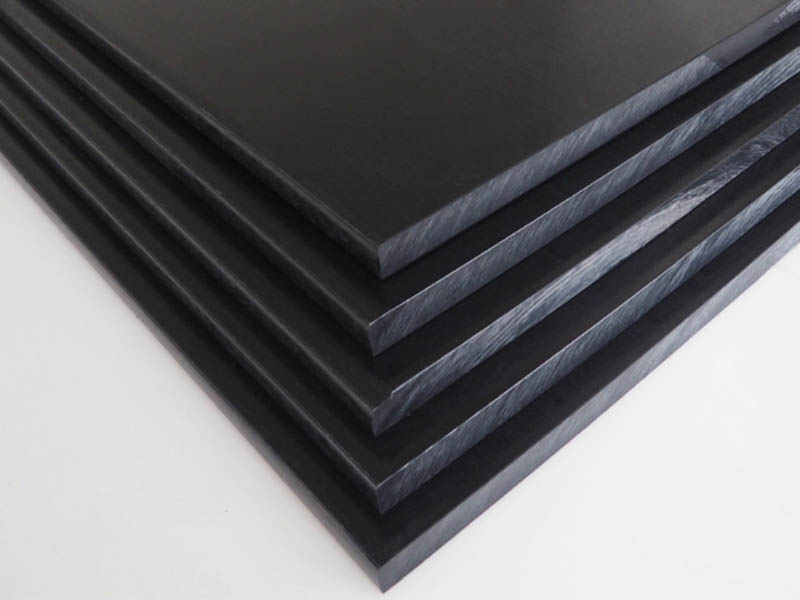

Aldehit polimer, polioksimetilen ve poliasetaldehit olarak da bilinen polioksimetilen (POM), bir mühendislik termoplastiğidir. Yoğunluğu 1,410-1,420 g/cm³ arasındadır. Mükemmel sertlik, mukavemet ve rijitliğin yanı sıra kimyasal direnç, boyutsal kararlılık, mekanik mukavemet ve düşük sürtünme katsayısına sahip olması, onu mühendislik uygulamalarında güvenilir bir malzeme haline getirir.

POM mükemmel mekanik özelliklere ve aşınma direncine sahip olmasına rağmen, işleme sırasında bazı sorunlarla karşılaşmaktadır. Bunlar aşağıda özetlenmiştir:

1. Çatlama sorunu

POM malzemeler, özellikle yüksek hızlı CNC işleme veya derin kesme sırasında işleme sırasında çatlamaya eğilimlidir. Bu, iç gerilimin serbest kalması veya malzemenin düzensiz soğumasından kaynaklanır. Çatlama oluşumunu azaltmak için makul soğutma ve işleme parametreleri şarttır. İşleme sırasında, homojen soğutma hızı sağlamak ve ani sıcaklık değişikliklerinden kaçınmak önemlidir. Uygun kesme sıvısı kullanmak ve kesme hızını ayarlamak da malzeme çatlaması riskini azaltmaya yardımcı olabilir.

2. Deformasyon sorunu

POM plastiği yüksek higroskopikliğe sahip olduğundan, işleme sırasında nem ve sıcaklıktaki değişiklikler deformasyona neden olabilir. POM malzemesi, sıcaklık arttığında genleşir ve özellikle büyük parçalar veya karmaşık şekiller işlenirken soğuduktan sonra büzülebilir. Ayrıca, POM işleme sırasında kesme kuvveti çok büyükse, özellikle ince duvarlı veya mikro yapıların işlenmesinde deformasyona neden olabilir.

3. Takım aşınması

POM düşük sertliğe sahiptir. İşleme sırasında nispeten az ısı üretse de, yapışkan özellikleri takımın hızlı aşınmasına neden olabilir. Takımın malzeme ve kaplama seçimi ve makul kesme koşulları, takımın kullanım ömrünü etkili bir şekilde uzatabilir. Yüksek kaliteli karbür takımlar veya kaplamalı takımlar, hassas kesme parametreleriyle birlikte kullanıldığında, takım aşınmasını azaltmaya ve işleme kalitesini artırmaya yardımcı olabilir.

4. Yüzey kalitesi sorunları

POM plastiklerin CNC işlenmesinde, yüzey kalitesinin sağlanması önemli bir zorluktur. Malzemenin özellikleri nedeniyle, yüzeyde çizikler, fırça izleri veya diğer pürüzlü dokular oluşabilir. Daha pürüzsüz bir yüzey elde etmek için, kesme parametrelerini ayarlamak, uygun takımlar kullanmak ve gerektiğinde yüzey kalitesini iyileştirmek için son işlem veya son işlem gibi farklı işleme tekniklerini uygulamak gerekir.

Etiketler :