FR, fiberglas takviyeli epoksi laminatlar için bir malzeme kategorisidir. FR-4 malzemesi, epoksi reçine ve alev geciktirici fiberglas kumaştan yapılmış takviyeli bir epoksi laminattır. Brom ilavesi sayesinde kendi kendine sönen bir malzemedir. Fiberglas laminatlar için kategori tanımları G-10, G-11, FR-4, FR-5 ve FR-6'dır. Bunlar arasında FR-4, günümüzde en yaygın kullanılan malzemedir. G-10, FR-4'ün öncüsüdür ve FR-4'ün alev geciktirici özelliğinden yoksundur. Bu nedenle, çoğu durumda FR-4, G-10'un yerini alır ve PCB üretimi için ideal bir seçimdir.

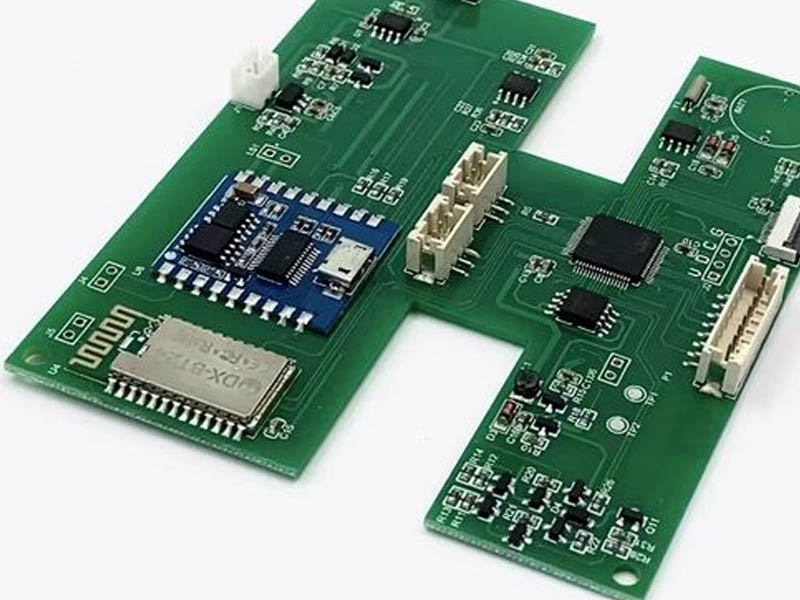

FR-4 malzemesi FR-4, mükemmel elektriksel yalıtım özellikleri, mekanik dayanımı ve yüksek sıcaklık direncine sahip yaygın ve yaygın olarak kullanılan bir alt tabaka malzemesidir. Çok az su emer ve FR-4, bir miktar mekanik dayanıma sahip bir elektrik yalıtkanı olarak en yaygın olarak kullanılır.

Bu malzeme, kuru veya ıslak koşullarda yüksek mekanik değerlerini ve elektrik yalıtım özelliklerini korumasıyla bilinir. Bu özellikler, iyi üretim özellikleriyle birlikte, bu sınıfı çeşitli elektrik ve mekanik uygulamalarda pratik hale getirir.

Cam geçiş sıcaklığı (TG) yaklaşık 115°C ila 200°C arasındadır. PCB üretimi için standart FR-4 malzemesi, iki ince bakır kaplamalı FR-4 katmanı arasında olacaktır.

FR-4, uygun fiyatlı olması sayesinde küçük parti veya prototip PCB üretimi için uygun bir seçimdir. Uygun fiyatı, tüketicilerin PCB üretim maliyetlerini düşürmesine yardımcı olur. FR-4, PCB üretiminde en yaygın kullanılan malzemedir. FR-4'ten üretilen devre kartları güçlü ve su geçirmezdir ve bakır katmanlar arasında iyi yalıtım sağlayarak paraziti en aza indirir ve iyi sinyal bütünlüğünü destekler.